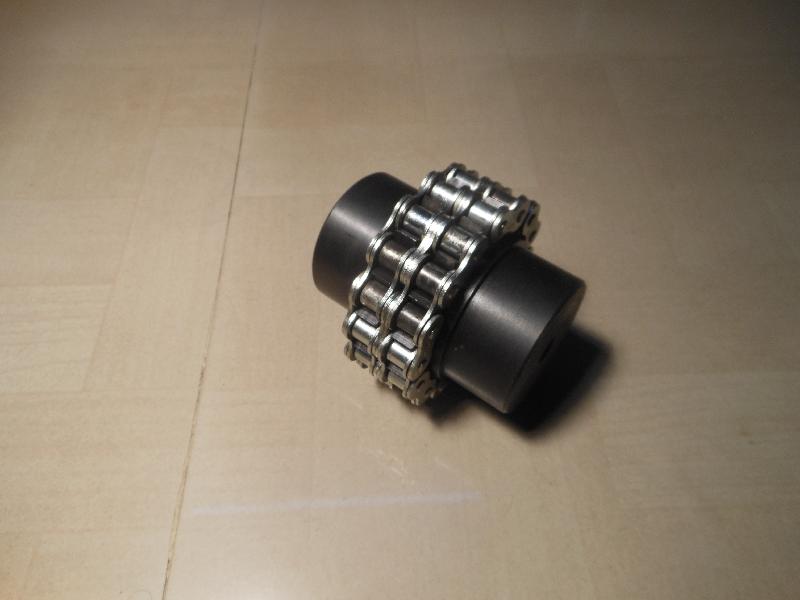

ROLLER CHAIN COUPLINGS

OUTSTANDING DURABILITY

The chain coupling performs outstanding durability with the torque on the coupling shared with the surface hardened teeth of the sprockets and the powerful roller chains that engage with the teeth.

EASY COUPLING AND DECOUPLING

Both shafts can be easily coupled or decoupled with a single joint pin inserted into or extracted from the roller chains.

ABSORPTION OF LARGE MISALIGNMENT

The clearances between the chains and sprockets and between chain components absorb the great positional misalignment of both shafts.

BODY CONSTRUCTION

The body consists of two dedicated sprockets with hardened teeth and two strand roller chains. The sprockets are coupled when the chains are wound around the sprockets. And decoupled with the chains removed. Therefore, transmission power can be coupled of separated without moving the transmission system.

CASING CONSTRUCTION

Casing For ease of mounting and inspection. The casing can be separated at a right angle to the shaft. The mating part to the hub is finished precisely to hold the hub firmly with no eccentricity. Furthermore. The other hole has a trapezoidal groove into which an oil seal is inserted for the prevention of oil leakage while holding the sprocket boss flexibly so that the flexibility of the coupling will not be lost. The coupling life is notably extended due to the prevention of both lubricant spatter and the infiltration of dust particles when installing the casing. Which ensures effective lubrication. The casing protects the unit from corrosion and ensures safe operation