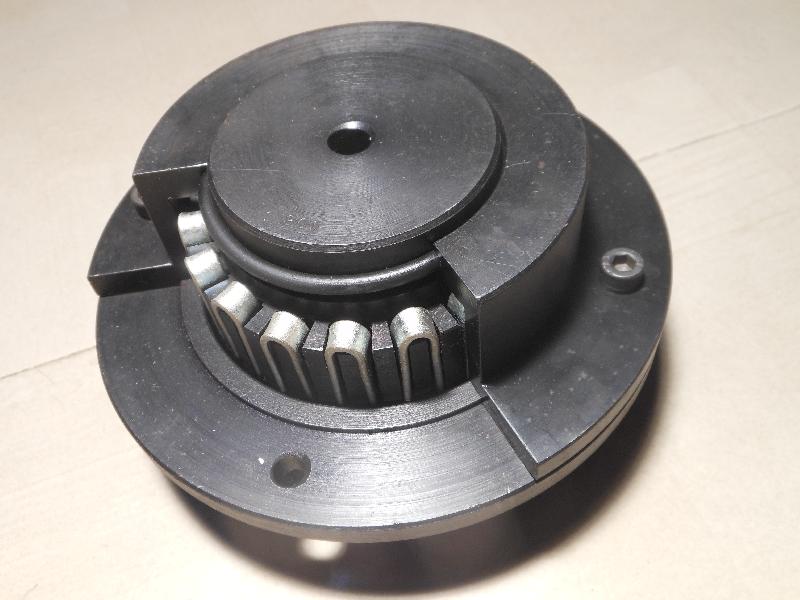

GRID COUPLING (SPRING GRID COUPLING)

KEVYA CORPORATION are distinguised by their MECHANICAL FLEXIBILITY and compensation of MISALIGNMENT of the connected shafts automatically without any loss of transmitted power during running. These coupling ensure greater flexibility because of their well designed tooth formation generated by INVOLUTE system to ensure uniform toothe PROFILE AND PITCH.